The Linear Fixed Adaptive Bending, or LFAB, collector represents a very different and promising approach to linear solar collectors. A picture of the LFAB collector is given in figure X. For a more in-depth and technical background on the geometry behind the collector and the design considerations, go to the background page.

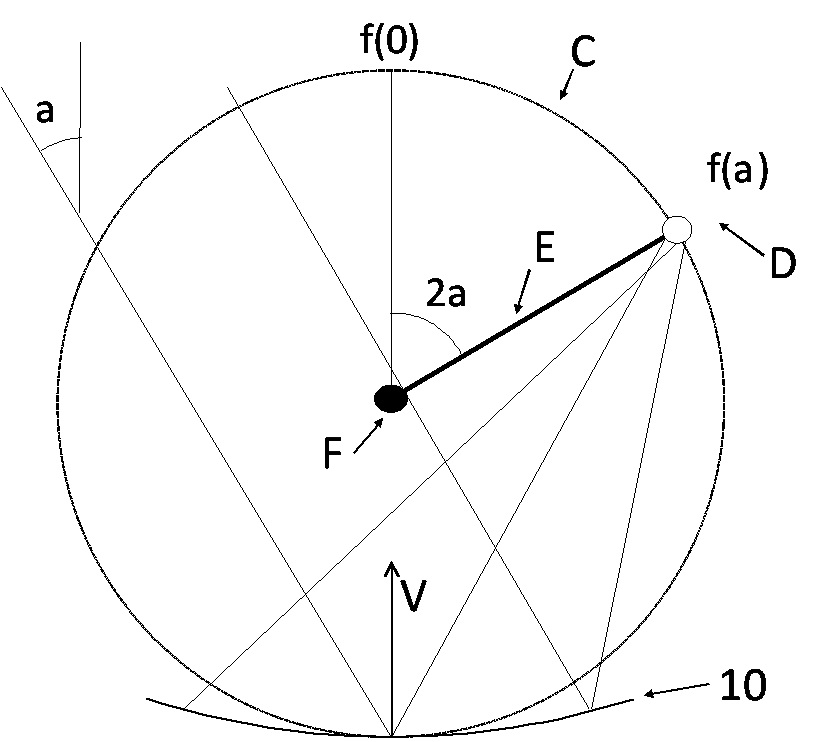

The collector consists of 2 slightly curved, fixed trough shaped mirrors and an absorber that moves along a natural circle of focus. As the direction of sunlight on the fixed mirrors changes, the position of the absorber must track to the right location on the circle of focus.

The end of the mirrors are attached by cabling to the axis of the absorber. As the location of the absorber tracks the reflected sunlight, the mirrors are flexed slightly to maintain a strong focus.

This collector represents something fundamentally new: a fixed mirror collector with few parts that has high concentration ratios. Many fixed mirror designs exist X, but usually have low concentration ratios. Low concentration ratios mean lower efficiencies for heat-based designs, and less cost saving for CPV (Concentrated Photovoltaic) designs.

The simple LFAB design in figure X can obtain a concentration ratio of 60 for incidence angles ranging +-30 degrees from normal. The more complicated design in figure X can obtain a concentration ratio of XX for incidence angles ranging XX. (More discussion of incidence angles and collector set-up here.) These concentration ratios are competitive with existing linear collectors.

We compare the LFAB collector to the most popular linear collectors, the parabolic trough and the linear fresnel collector. For a more general comparison to a larger class of collectors and to PV arrays, go to the comparisons page.

A schematic of a parabolic trough is shown in figure X. The parabola is the perfect shape to concentrate light. In this case

the light is concentrated along one axis instead of two, creating a linear collector. An analogous point collector would be a

Parabolic troughs are the most commercialized of all concentrated solar collectors, linear or otherwise. Xcheck thisX Large parabolic trough plants exist in X, X, and X.

The success to date of the parabolic trough is due to the simplicity of the design, as well as the maturity of the technology. However, there are relative weaknesses to the parabolic trough design.

A popular possible alternative to the de facto parabolic trough is the linear fresnel collector. See figure X. Several long narrow mirrors are placed next to each other. They are relatively oriented so that they concentrate the sun at a certain line of focus. In a 2-d schematic of the collector, such as figure X, this is represented as sunlight concentrated at one point.

All of the mirror's rotation are linked. If the direction of incoming light changes, geometry dictates that all of the mirrors need to rotate exactly the same amount to maintain focus at the same point. This makes for an elegant and simplified design.

The Linear Fresnel Collector has its mirrors low to the ground, reducing wind vulnerability. It also has a natural tradeoff compared to parabolic trough collectors - Linear Fresnel collectors use the ground more efficiently when the sun is overhead, but have smaller light intensities when the sun is closer to the horizon (assuming an East-West collector orientation of the collector, related issues happen for any orientation). (See figure X?) A couple of issues of LFC's are

The LFAB collector is still in the development stages, but has advantages over both of these other linear collector designs. It possesses

The LFAB design shares many traits with LFCs. It has good land usage but suffers from lower light intensities when the sun is closer to the horizon. It has mirrors that are lower to the ground. But it has far fewer parts, and thus has the potential for substantially reduced cost. It has the potential to be less expensive than any known commercially developed concentrator with similar concentration ratios.

Natural technical questions for the LFAB collector at its present stage of development are

These 4 questions will be addressed in the next sections, as will the present stage of development of the LFAB collector.

Fig. 1: Profile model of solar collector. D is absorber, F is pivot point. Parc Mini-France

One of the benefits of the design is having a fixed, well, mostly fixed mirror. As the mirror is lower to the ground, a larger mirror can be designed due to less structural requirements of the fixed mirror and the smaller size of the absorber.

But, you say, the mirror is not fixed! The flex, however, is quite slight. For a mirror as in figure X where each mirror is 2 feet wide, the total flex of the mirror during operation is 1.6 inches. The design in figure X has far less flex, just 1/2 an inch for a collector that is 4 feet wide. This slight flex makes the design easy to make without worrying about fatigue issues.

The slight bend of the mirror does mean that glass mirrors are not a likely proposition. Other alternatives, such as polishing aluminum or applying a mirror film on a bending substrate, are available.

The LFAB collector is in early development. The theory is relatively well developed (though there is asignificant optimization issue that needs further thought, for those of you that are mathematically minded), and a patent has been applied.

In addition a prototype has been built that shows definitively that the mirror surface can be manufactured so that when flexed, it can achieve concentration ratios that come very close theoretical ones.

To make the design work, a cam element is needed on the axis of the absorber arm. A cam element has been built, and the flex of the mirror from rotating the absorber arm has been shown to be very close to theory.

A few more prototypes need to be made to test further aspects of the design. These will be done in short order. A summary is given below.

In addition, the more efficient design shown in figure X will be built and tested as well.

It is believed, and will soon be demonstrated, that inexpensive syncing of mirror bend and absorber motion can be achieved. In addition, the design is promising for using feedback for tracking. If the absorber is slightly off in location, a lot of concentrated light lies on one side of the absorber. A thermistor placed across the absorber should be able to accurately capture this. See figure X.

Note that one benefit of using feedback for tracking is a reduced need for calibration. Ideally this design can be assembled and placed almost anywhere with slight errors in alignment not causing any issue.

The design intrinsically focuses light the best when light is normal to the collector. The simpler design in figure X can maintain a concentration ratio of 60 for light within 30 degrees of normal. This basically dictates an east-west arrangement of the linear axis of the linear collector. See figure X.

The more complicated design in figure X can maintain a concentration ratio of 120 for light within 45 degrees of normal, or a ratio of 160 (check) for light within 30 degrees of normal. This suggests an east-west arrangement as well.

The incidence angles of the sun at various times at a couple of latitudes is shown in table X. Basically, for similar latitudes, for the simpler design, one season change at the solstices will allow for collection of sunlight at the desired concentration ratio for a 10 hour (check) day. For the more complicated design, no season change is required, the tester can be set almost flat at 20 degree angle for a 10 hour day in the summer, 8 hours during the winter.